The inflatable roof is a flat Cairbag® (“pancake type”) solution, made of a 3 dimensional (3D) rubber (or 3D textile), providing a floating platform, which is to float directly on top of the liquid filling the Linerbag or is inserted into a roof sleeve type of provision for example in case the 3D material is not compatible with the liquid stored or in cases or intended re-use of the 3D part in exchangeable Linerbag products.

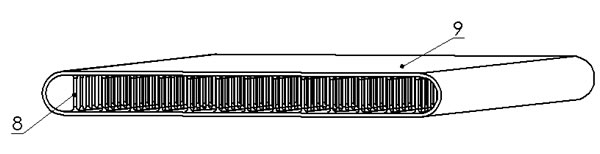

This type of roof is based on so called 3D textile, as in the drawing above and comprises two airtight, non-permeable textile sheets (numbered “9”) and a large quantity of threads (numbered “8”) randomly positioned in between these two sheets. Creating a small overpressure in between the two sheets of textile will all these threads (of equal length) to be tensioned, thus creating two flat surfaces (virtually to the edges).

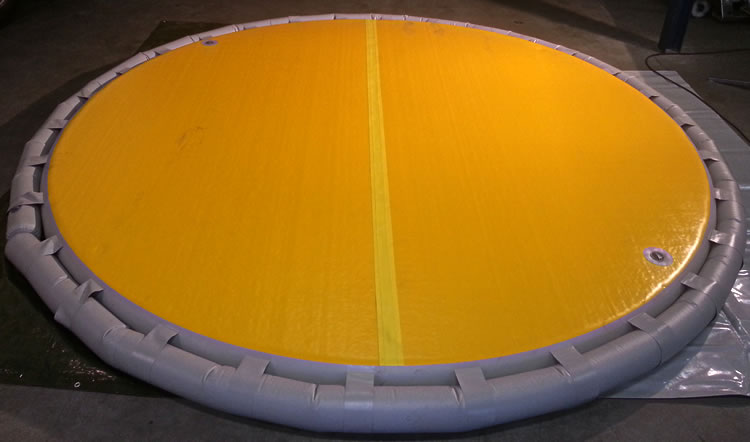

The 3D inflatable “Cairbag®” working platform comprises two components:

- The main 3D rubber or textile inflatable working platform of a diameter which is 1-2% smaller than the tank internal diameter (which is 12 meters in this proposal) with a dedicated air connection.

- - A separately inflatable outer ring at the circumference of the 3D Cairbag platform, filling the gap between the 3D Cairbag platform and the inner tank wall. This ring has also a dedicated air connection.

The 3 dimensional rubber or textile used for this type of Cairbag product will create a constant thickness over its full surface, which thickness will be either 200 or 330 mm, in this proposal stage. The seam along the circumference will, together with the airtight, non-permeable 3D rubber or textile assure a full enclosure allowing for sufficient working pressure (assumed in this proposal stage to be some 200 millibar) to allow for persons to stand and work on it for maintenance purposes.

The outer ring, which is only applied in case of a stand-alone type of internal inflatable floating roof application either with or without an “open-top” Linerbag product, is made of a wear and tear resistant rubber or textile which will form itself in accordance with the geometry and shape of the inner tank wall and the 3D Cairbag platform thus ensuring that there are no gaps between the inner tank wall and the working platform and that there is enough friction to ensure the stability of the working platform.

Two pneumatic (air) connections (one for the main 3D platform part and one for the outer ring,if used), will be positioned on the top of the Cairbag platform to allow for the in- and deflation of the Cairbag platform and the outer ring. An external pneumatic system is included in the total Cairbag system, meeting ATEX specifications and requirements. This pneumatic system may either take air from an instrument air system (if available on site) or use a dedicated air pump. The system includes furthermore over- and under-pressure monitoring devices regulating the air supply and relief of the Cairbag internal air space, as well as over- and under-pressure safeguarding devices. The air supply, discharge hose will be routed through an existing provision (usually the manhole) in the roof.