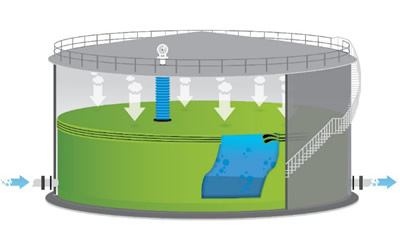

The Linerbag product is a device capable of holding liquids when applied inside fixed roof storage tanks, designed and manufactured such that it contains all the fluid stored in the storage tank in a manner that the fluid is separated from both the entire steel tank structure as well as from the air/space above the fluid. The Linerbag product is made of a flexible reinforced thermoplastic or rubber material, which is resistant against the liquids to be stored and of very low permeability.

A Linerbag product forms an enclosure for the liquids which by design shall prevent leakage of the liquid into the steel tank. The function of the steel tank becomes that of providing structural strength rather than a liquid enclosure (conform API-650). As most tanks in which Linerbag products will be applied have been designed and built with a liquid tight specification, the steel tank thus forms a second barrier against liquid spills. A leak detection system, as commercially available, is recommended to be installed in between the Linerbag and the steel tank floor allowing for an early warning in case of an unforeseen Linerbag leakage and hence for corrective actions prior to such leakage becoming an environmental spill.

A Linerbag product forms an enclosure for the liquids which by design shall prevent leakage of the liquid into the steel tank. The function of the steel tank becomes that of providing structural strength rather than a liquid enclosure (conform API-650). As most tanks in which Linerbag products will be applied have been designed and built with a liquid tight specification, the steel tank thus forms a second barrier against liquid spills. A leak detection system, as commercially available, is recommended to be installed in between the Linerbag and the steel tank floor allowing for an early warning in case of an unforeseen Linerbag leakage and hence for corrective actions prior to such leakage becoming an environmental spill.

The air inside the tank remains outside the Linerbag enclosure while the Linerbag prevents virtually all contact between the liquid and the air in the tank. There is a relatively small liquid / air contact surface in the bellow(s) of a Linerbag system exposing the air content of the below to liquid based vapors, in case bellow are used. A blather provision accommodating the air variations of the bellows may be included in the system to further mitigate emissions from the tank.

In order to equip a storage tank with a Linerbag product, the existing piping, connections and instrumentation require preferably to remain unchanged and to be able to be positioned inside the fluid inside the Linerbag if such is required to perform its functions and to allow for the liquid to flow in and out in a controlled manner, such that the tank and all equipment and provisions maintain their functionality and that all normal operations can be maintained. In order to achieve this, the Linerbag is equipped with connections, which allow for easy installation and which are designed and manufactured to guarantee / make sure that the Linerbag remains a fluid tight liquid enclosure. The Linerbag is furthermore provided with a manhole which makes it possible to enter the empty, gas free Linerbag safely for installation, inspection or other purposes.

The Linerbag system is an enclosure with provisions both at the cylinder part of the sidewall as on top of the Linerbag. The sidewall provisions of the Linerbag product allow for the in- and outflow of the liquid, for access both into the tank as well as into the Linerbag via the manhole and for draining liquids from the Linerbag system. The top of the Linerbag product allows for metering and safeguarding provisions matching the corresponding devices mounted on top of the roof of the tank.

The Linerbag system is an enclosure with provisions both at the cylinder part of the sidewall as on top of the Linerbag. The sidewall provisions of the Linerbag product allow for the in- and outflow of the liquid, for access both into the tank as well as into the Linerbag via the manhole and for draining liquids from the Linerbag system. The top of the Linerbag product allows for metering and safeguarding provisions matching the corresponding devices mounted on top of the roof of the tank.

Metering devices like for temperature and level metering and the provision allowing for product sampling requiring access into the stored liquid require bellow type of provisions, often with an internal standpipe, which connect the top of the Linerbag (roof) with the flanged connection on the roof of the tank.