The fixed volume inflatable component and maximum weight limitations

Fixed volume inflatable systems may, for example, be used for mobile tanks traveling regularly or incidentally in between two adjacent countries, each allowing a different mandatory maximum total weight of the means of transport. The fixed volume inflatable component system may thereby cater for the tank and truck to remain below the legally allowed maximum weight while enabling the transportation of the maximum possible payload in both countries.

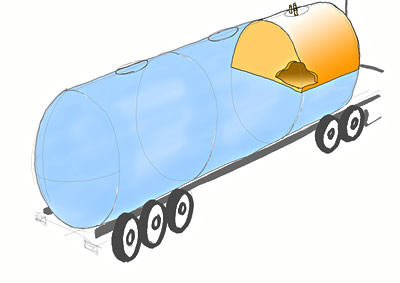

The design shows a fixed volume inflatable component of a slosh mitigation product inside a tank on top of the liquid fill of the tank (own design, made by “Hardt”).

The design shows a fixed volume inflatable component of a slosh mitigation product inside a tank on top of the liquid fill of the tank (own design, made by “Hardt”).

The fixed volume inflatable component of the inflatable component system is to be inflated for use in the country with the lower allowed maximum weight. The volume of the inflated fixed volume component reduces the maximum possible volume of liquid that can be loaded, hence thereby reduces the total weight of the mobile liquid holder and cargo at maximum fill. The inflatable component is kept deflated when the mobile tank is only used in the country with the higher allowed maximum weight (assuming the tank design matches this maximum allowed weight when 100% filled at the specific gravity of the liquid product). Subject to the frequency of this and the cleaning aspects (see chapter 6.4), the inflatable element may be either permanently or intermittently installed, and may be air or any other gas filled component subject to, for example, safety requirements.

In the Netherlands a tank trailer, for example, (with a net mass of 12x103 kg), which is allowed to carry a maximum total mass of 50x103 kg by the Dutch Law, could have a tank of some 38,000 litres (resulting in 38x103 kg cargo in case of use for liquid cargoes with a density of 1000 kg/m3). This tank could be provided with a fixed volume inflatable component of 10 m3, which should be inflated in case this truck is to drive in(or into) Germany, where a maximum total mass of 40 tonnes is allowed by Law. A 10-cubic meter fixed volume bag, when inflated, reduces the effective volume, available for the liquid load, of the tank from 38 m3 to 28 m3 equivalent to 28x103 kg liquid, thus keeping the total mass within the 40x103 kg legal limit in Germany when 100% filled. The fixed volume inflatable component thus ensures that the tank, both in the Netherlands, as well as in Germany, can be filled without exceeding the maximum allowed weight of the tank truck and cargo in both countries. Note that in Germany the liquid part of the fill equals (28/38 =) 73,7%, the remaining 26,3% is filled with the inflated component. In case the liquid would be subject to ADR regulations, the tank would have to be provided with (at least) 4 baffle plates (adding about 1000 kg to the truck net mass) in accordance with [3.01], article 4.3.2.2.4. Such baffles are not mandatory at a 100% fill rate.

The fixed volume inflatable component and axle over-loading

The research encountered besides situations of total truck weight overloading, the problem of a single axle being overloaded, even when the total truck weight is within its limits. Axle overloading, in both a static as well in any dynamic situation, is in many countries not allowed by law. The problem of dynamic axle overloading, caused by a sloshing liquid, is recommended to be eliminated by applying a slosh mitigation product.

An inflatable component may also be used to avoid axle overloading at near 100% fill levels in static situations of mobile liquid holders, especially in cases for which that avoiding such axle overloading would result in having to reduce the liquid cargo and thereby introducing the possibility of more liquid sloshing and dynamic overloading.

Truck engines with a single driven axle pulling a tank trailer are most commonly prone to static axle overloading, especially in cases a tank trailer has been designed for being pulled by dual-driven axle truck engines. The tank trailer imposes a too high a load on to the driven axle of the truck.

In case avoiding axle-overloading would only be possibly by reducing the level of liquid loading, hence to reduce the payload. In this case the use of an inflatable component may be attractive. A relatively small fixed volume component, to be fixated inside the tank directly over the otherwise overloaded axle.

In case avoiding axle-overloading would only be possibly by reducing the level of liquid loading, hence to reduce the payload. In this case the use of an inflatable component may be attractive. A relatively small fixed volume component, to be fixated inside the tank directly over the otherwise overloaded axle.

Another interesting application of a fixed volume inflatable component is the component positioned and fixated at the rear end of the tank to ensure that the liquid, partially filling the transportation tank, is positioned over the driven axle rather than over the rear axles of the tank trailer. Thus creating more loading of the driven axle as otherwise would have been the case. This may be necessary especially in icy winter conditions, driving on sloping roads in a mountain area whereby the driven axle may be insufficiently loaded to pull the truck out of a stand-still when driving uphill (like in case of stop-and-go traffic in a traffic queue).